Adding Kevlar to a Hull Laminate Does Not Make It Collision-Proof

EMPLOYING A LAYER OF KEVLAR IS OFTEN JUST A MARKETING PLOY

Contrary to marine industry myth, adding a layer or two of aramid fibers to a laminate does not turn it into a super-material, able to sustain with impunity collisions at sea with steel containers and other dangerous flotsam.

I am not personally a big fan of including aramid (e.g. Kevlar®) in the laminates of purpose-built cruising vessels because:

Aramid is relatively expensive, so pushes up the price of a yacht.

Aramid fiber does not wet out well with polyester resin and only slightly better with vinylester resin. Indeed, aramid fiber generally requires the use of an appropriate epoxy resin matrix if it is to develop anything approaching its full mechanical properties in a laminate.

And anyway, just as much can be done in terms of adding strength to a hull against the potential collision by properly engineering and "beefing up" a conventional S-glass or even E-glass reinforced polyester or vinylester laminate.

The only advantage that aramid potentially offers is increased strength per unit weight. However, the weight-saving it affords in common circumstances is not sufficiently significant in any but ultra-high-performance vessels — which most cruising yachts are not. And the few extra pounds per unit strength required to achieve the same results in an all-glass vs a glass+aramid hybrid are of little concern in most cruising yachts.

The bottom line is that the inclusion of Aramid in the laminate is generally little other than a marketing gambit, intended to give the impression of a serious addition to collision-resistance.

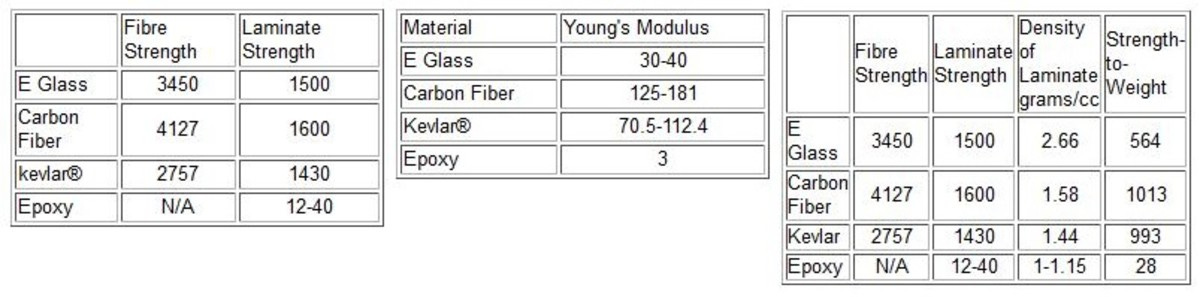

Most people misunderstand the mechanical properties of aramid. It is more "elastic" than either E-glass or S-glass fiber (namely, it has a higher "Young's modulus"). But contrary to popular misconception, that does not necessarily mean it’s “stretchier”. What it means is that it can sustain higher loads before it is pushed out of its elastic range of deformation (the range in which it will return to its original shape when the load is removed) into its plastic range of permanent deformation.

This means that, in all-fabric layups such as soft ballistic armor, it will absorb tremendous loads and energy by deforming and not rupturing. However, when set into a laminate composed of a polymer resin matrix and fabric reinforcing, the behavior of the composite laminate is not strictly comparable to a lay-up of soft armor. A few minutes perusing the charts below for comparative tensile strength, Young's modulus, and strength-to-weight ratio clearly illustrate what I'm saying.

As a boatbuilder, I'm happy to include aramid in a laminate if a customer absolutely wants it, but I cannot in good professional conscience say I believe in it. And I personally much prefer to properly engineer the glass laminate and additionally employ design features such as a watertight collision compartment at the forward end of the waterline (extending back a few feet from the stem) than do, what I call, the "Kevlar marketing jig". And I am much more confident that the results will be predictable and ultimately more to my client’s or customer's best interests.

— Phil Friedman

Copyright © 2023 by Phil Friedman — All Rights Reserved

An early version of this article originally appeared on the author’s LinkedIn blog, then later, in Passagemaker magazine.